History of the company

The history of the plant began in 1881 with the creation of the enterprise “Kosharsky Machine-building and iron-copper-Metallurgical Plant”.

After the victory of the Great October and the expulsion of foreign interventionists from Belarus, the rebirth of the plant began. At first, workshops for the repair of various machines and mechanisms were organized here, and in March 1925, an iron foundry and machine-building plant “Metal” was established on their basis. Three years later, in 1928, Metal merged with the Voskhod plant and the Central Agricultural Workshops. On their basis, a fairly large enterprise was formed – the Kommunar plant. Since 1934, the plant has been specializing in machine tool construction. The first machine was released in January. This year, several broaching, centering and hydraulic hacksaw machines were produced. In the same year, 1934, the plant was named after Sergei Mironovich Kirov.

The peaceful creative work of the Soviet people was interrupted by the war. In the very first days, fascist bombs destroyed everything at the plant that was created by the hard work of the collective during the first Soviet five-year plans. The Nazis turned the production buildings, offices, equipment into a pile of ruins. Kirov residents fought with weapons in their hands against the enemy on the fronts and in partisan detachments, forged victory by working at the country’s defense enterprises.

Immediately after the liberation of Minsk from the Fascist invaders, many Kirov residents returned to their factory again and took a direct part in the restoration of its production buildings. Already in November 1946, the first machines were produced at the plant. The plant began to specialize in the production of broaching machines. In 1948, Kirovtsy mastered the production of horizontal-broaching machines of semi-automatic principle of operation, and later – and horizontal-broaching machines. Only during the years of the first post-war five-year plan, 28 models of new machines of original design were developed and mastered at the plant. Some of them were not inferior in their technical characteristics to similar machines of well-known foreign companies.

In subsequent years, the plant developed and mastered various modifications of metal-cutting machines, including hacksaw and tape-cutting, vertical and horizontal-broaching. In addition to metal-cutting machines, the production of hydraulic presses, stone processing plants and a wide range of woodworking machines for industrial and domestic purposes was mastered. The plant, with its machine-tool products, participated in the equipment acquisition of such large-scale industrial facilities as GAZ, ZIL, MTZ, MAZ, VAZ, KAMAZ and many others.

In February 1973, Vyacheslav Frantsevich Kebich, a talented engineer and production organizer, was appointed director of the plant. The new director has been working hard and systematically on the selection, placement and education of personnel, raising the level of all organizational and ideological work in the factory units. The issues of a clear organization of production, reconstruction of workshops and sites, full loading of people and equipment, persistent struggle for strengthening labor discipline were put to the fore.

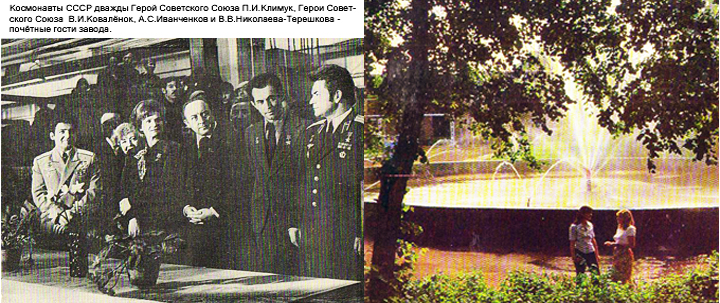

A significant milestone in the history of the plant was the factory-wide open party meeting held on April 2, 1976, at which the first secretary of the Central Committee of the Communist Party of Belarus, Pyotr Mironovich Masherov, made a report. After the meeting, Masherov P.M. got acquainted with the plant and met with the staff of the enterprise.

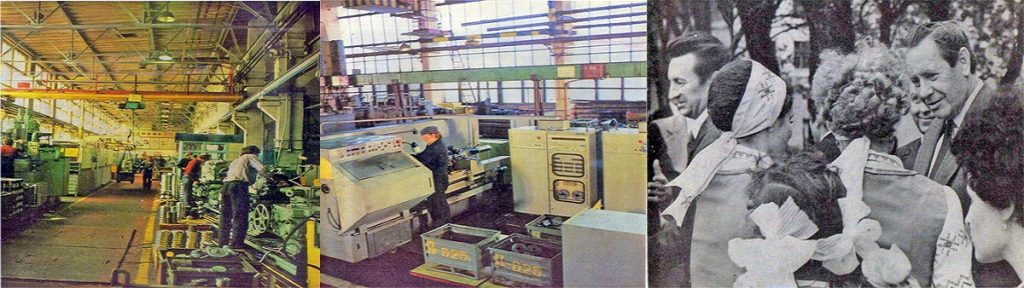

The plant belongs to enterprises with a closed production cycle and has in its structure forging and procurement, welding, thermo-galvanic, mechanical assembly and painting and packaging production.

- In recent years, the plant has specialized in the production of the following types of machine tools:

- broaching machines (horizontal, vertical and special based on them);

- band-cutting machines for cutting ferrous and non-ferrous metals of various profiles, ensuring the introduction of resource-saving technologies;

- rail-cutting machines of several modifications for simultaneous cutting and drilling of holes of volumetrically hardened rails at metallurgical plants and rail welding trains (RSP);

- circular saw cutting machines designed for cutting with circular saws of ferrous and non-ferrous metals with automatic and manual operation;

- hacksaw cutting machines for cold metal cutting;

- abrasive cutting machines for high-performance pipe cutting;

- vertical drilling tables for drilling, countersinking and deploying holes;

- woodworking machines for industrial and household purposes;

- peat wagons of narrow gauge (TSV-6A, TOV-1).