-

Address Minsk, Dolgobrodskaya str. 18

-

Phone +375 (17) 375-86-09

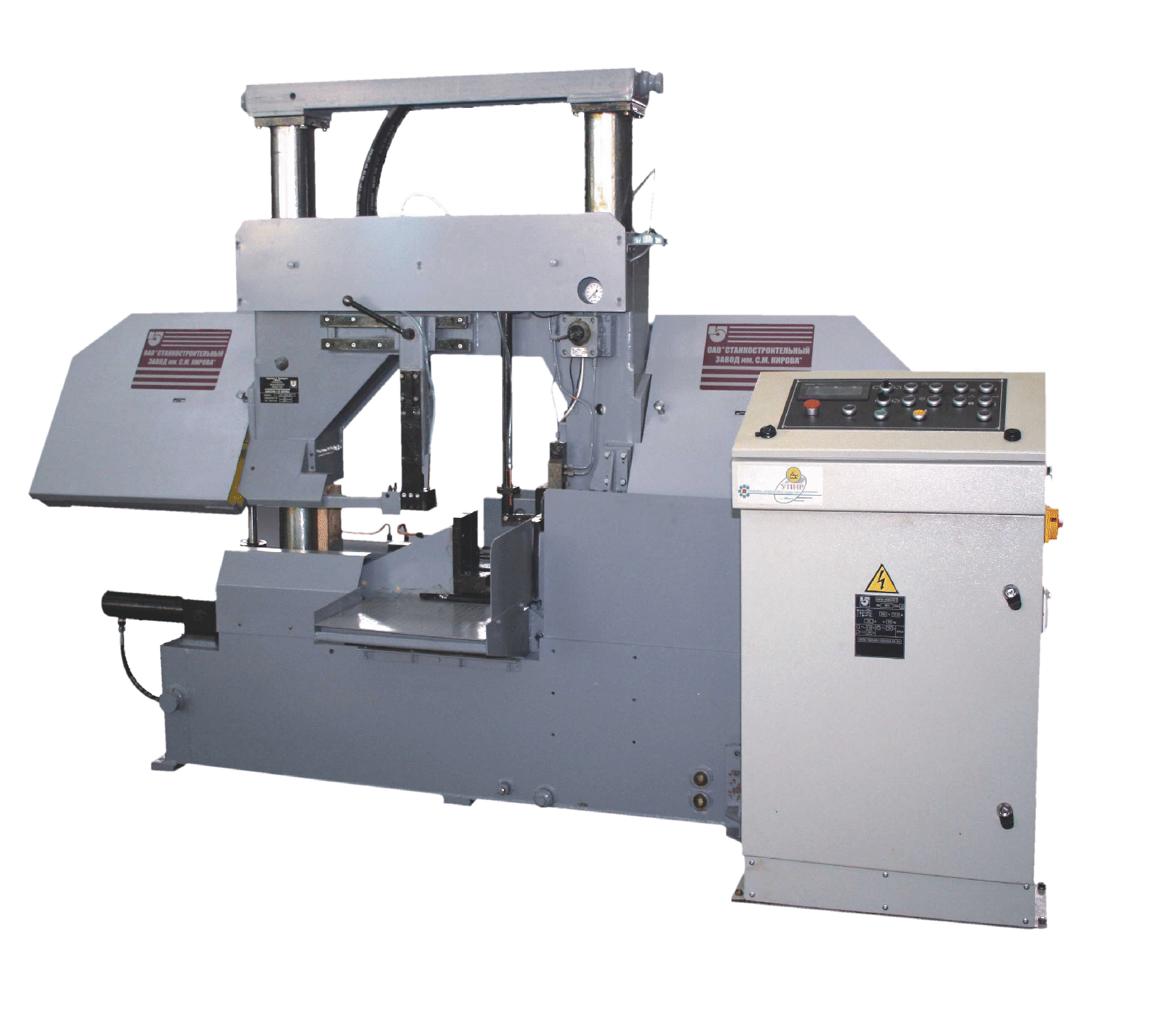

Automatic belt-cutting machine model MP6-1920-001

Description

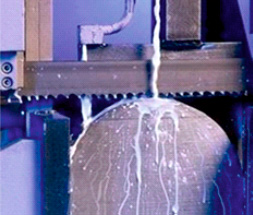

The machine is designed for cutting ferrous and non-ferrous metals of various profiles into dimensional blanks.

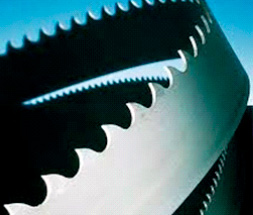

A bimetallic saw in the form of a closed band with teeth made of high-speed steel on a cobalt base or a hard alloy is used as a cutting tool.

The introduction of band-cutting machines will provide Maximum benefits and advantages for your company:

minimal metal waste into the chips by reducing the width of the cut;

reducing the power of the main drive and reducing power consumption;

increasing the productivity of the segments by increasing the cutting speed and the minute feed of the cutting tool.

The use of the machine is especially effective when cutting expensive metals and alloys, as well as when cutting various thin-walled profiles.

The electrical circuit for controlling the machine cycle is built on the basis of a programmable controller (PC).

Technical specifications:

Dimensions of processed parts

up to 400 mm

400х400 mm

Dimensions of the cutting tool (tape)

34х1, 1х5450 mm

Speed

20...120 m/min

Main drive power

4 kW

Weight

3000 kg

Length

2280 mm

Width

3025 mm

Height

1960 mm