-

Address Minsk, Dolgobrodskaya str. 18

-

Phone +375 (17) 375-86-09

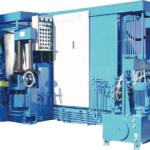

Drilling and cutting disc machine MP6-1515-003

Description

The machine is designed for simultaneous drilling of 6 holes in volume-hardened rails, as well as for cutting rails.

The holes in rails P65 and P75 are processed with carbide drills, and in rails P50 – with high-speed drills according to GOST 10903-77. Rails are cut with saws, the teeth of which are equipped with a hard alloy, as well as disc segment saws for metal according to GOST 4047-82. Cutting is performed at an angle of 90 ° to the axis of the workpiece being cut.

The machine can be integrated into mechanized lines for processing rails of rail welding trains and in the equipment of switch plants.

Technical specifications:

Processed rail

P65; P75; L=500... 12500 mm

Tool Dimensions

saw D 630, drill bit D 36 mm

Speed

12,3 m/min

Main drive power

15 kW

Weight

9400 kg

Length

5130 mm

Width

2400 mm

Height

1840 mm