-

Address Minsk, Dolgobrodskaya str. 18

-

Phone +375 (17) 375-86-09

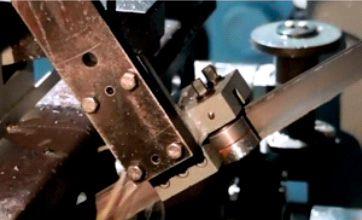

Drilling band-cutting machine for railway rails model MP6-1968

Description

The MP6-1968 model machine is designed for simultaneous cutting and drilling of bulk-hardened and non-heat-treated rails P50, P65 and P75 (additionally equipped with two interchangeable drilling heads (left and right) for processing the rail P50).

Cutting is performed at an angle of 90 ° to the axis of the rail being cut.

For cutting, a bimetallic band saw is used in the form of a closed tape with teeth made of high-speed steel on a cobalt basis.

Carbide drills are used for drilling holes.

Compared with machines like MP6-1515-003 and MP6-1750, in which saw blades are provided for cutting, the machine mod. MP6-1968 provides a number of advantages:

increased cutting performance by increasing the cutting speed and feed rate compared to cutting with a disc segment saw;

reducing the cost of preparing the cutting tool for work due to the higher resistance of the bimetallic saw belt in comparison with the disk segment saw;

reduction of electricity consumption by reducing the power of the main drive, as the width of the cut is reduced several times;

saving metal by reducing its waste into chips.

Technical specifications:

Processed rail

Р50; Р65; Р75 mm

Tool Dimensions

band saw drill bit D36 mm

Speed

40...120 m/min

Main drive power

Total 40 kW

Weight

6500 kg

Length

3460 mm

Width

2250 mm

Height

1900 mm